How Energy

Anchorage

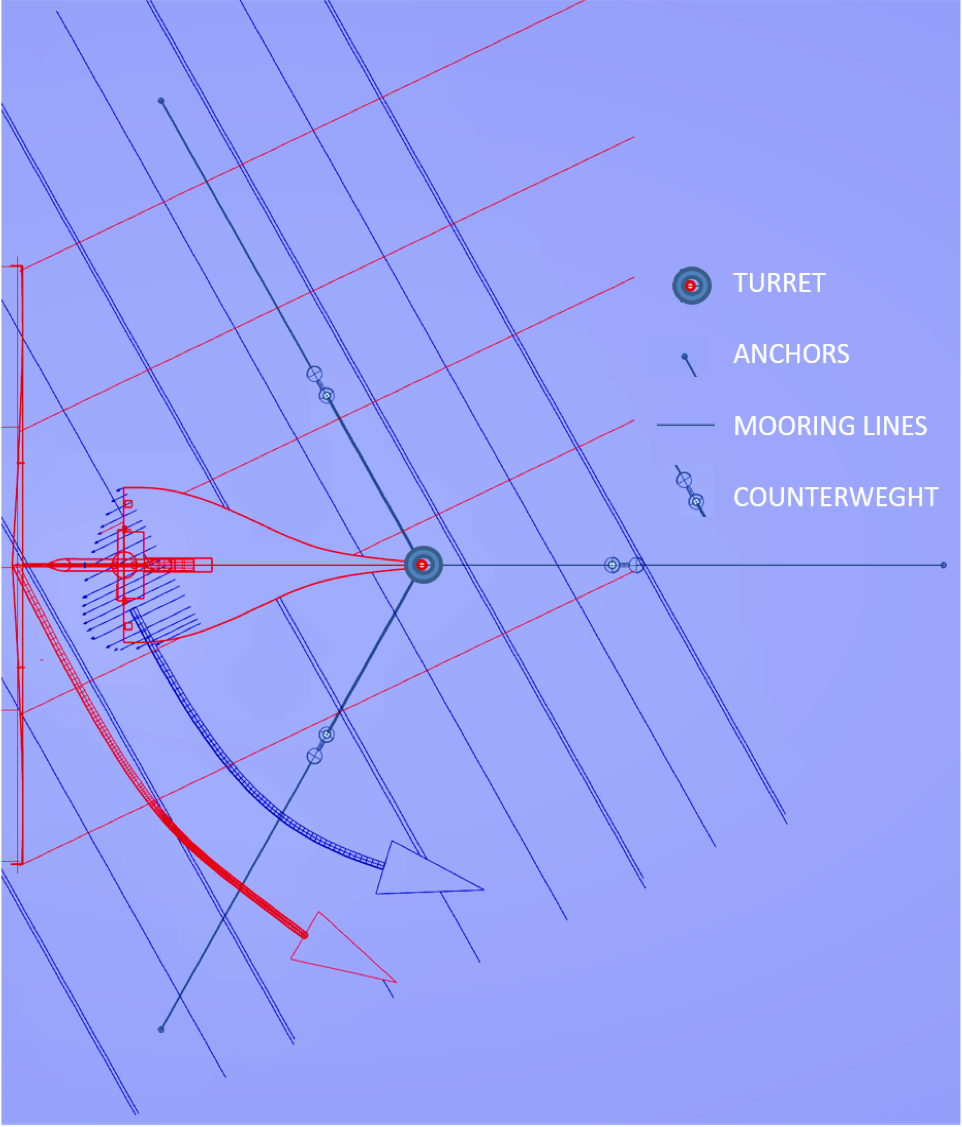

- Three or more fluke anchors equally spaced

- Anchoring lines connected to the central, rotatable part of the turret

- Counterweights connected to each anchoring line to increase rough weather stability

- Deep sea anchorage (< 3000 m)

How Energy

Rough Weather

The wind pressure on the large propeller and the damping of the anchoring device greatly stabilizes the unit.

- Pitch and roll amplitudes of 2 degrees are not considered to influence the production.

- The unit has a natural period in pitch of 15 s and

21 s in roll

How Energy

The mast

Is designed as an aerodynamic, balanced fold-down mast for easy access and maintenance of the nacelle and propeller blades.

Hight from sea level = 240 meters

Propeller diameter = 380 Meters

(Patents exist)

How Energy

The hull

Designed on the well proven Ramform hull, modified for the purpose by the same (Ramform) designer. (Patents exist)

How Energy

The blades

The propeller blade is constructed like an airplane wing fitted with actuators and flaps.

- Dimensioned for fatigue loads

- Placed behind the aerodynamic shaped mast

- Easy access for cleaning and maintenance

How Energy

The nacelle

Is fixed to the mast and do not need to rotate

- 3×15 MW generators with possibility to fit a fourth

- Common shaft with bearings

(Patents exist)

How Energy

Energy requirements

Total energy consumption for production, including auxiliary systems is totalling 57 KW/kg

- 46 KW/kg for H2 production

- 7 KW/kg for liquefaction to LH2

- 4 KW/kg for production and ships function auxiliary systems

How Energy

Energy production

Wind energy is extracted by a 2-bladed propeller with a diameter of 380 m

- Efficiency of 0,47% at wind speed of 11 m/s, including mechanical and other losses

- Optimised turbines from traditional up to 10m/s to 12 m/s increases theoretical energy harvest with > 40%

- Turbunes to be designed with 5% overload

- Fuel cell backup power systems